Contract manufacturing for diagnostic and life science

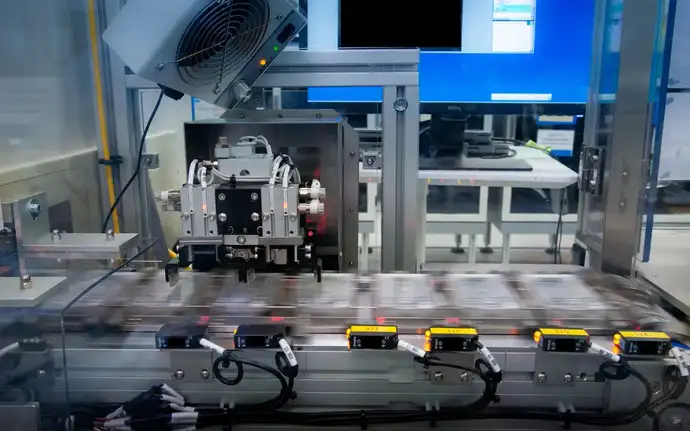

High volume manufacturing for diagnostic or life science research consumables. Packaging line with full automation.

High volume automated production: scaling success

With an in-house automation team exclusively dedicated to consumable production lines, we ensure a seamless transition to high volume production as demand increases. We employ a range of automation approaches suited to different stages in the market and the product lifecycle. This includes low volume, semi-automated work centers, and dedicated high volume automation lines. This allows you to control capital investment and concentrates on the highest ROI activities first.

Manufacturing and engineering collocated

Our manufacturing and development teams are collocated, working side-by-side, guaranteeing the highest application engineering. With experts spanning engineering and scientific disciplines, we are able to rapidly troubleshoot any issues and drive continuous improvement, throughout production.

Quality assured

Quality and compliance are non-negotiable. We adhere to exacting standards, ensuring our products consistently meet or exceed the highest quality.

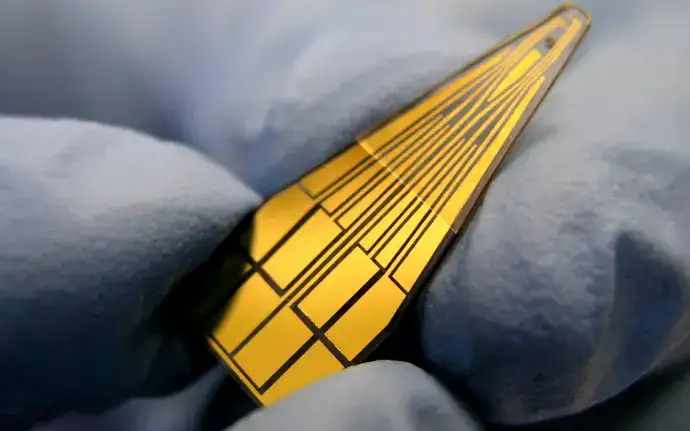

ISO 6 & 7 cleanrooms

Our extensive cleanroom facilities are designed and built to comply with ISO 6 & 7 cleanroom standards. Our cleanroom areas feature ultra-filtered air, cascading pressure differentials, airlocks and procedural controls to ensure these spaces remain free of contaminants.

Collaborative partnerships

Collaboration is at the core of our values. We work closely with you to understand your unique needs and aspirations, fostering strong partnerships that lead to successful product outcomes.

FAQs

New discoveries and innovations within the diagnostic and life science industries, lead to the need for design and manufacture of complex diagnostic instruments and consumables. SCHOTT MINIFAB is a manufacturer of diagnostic consumables, including fully integrated sample-to-answer consumables, custom spotted microarrays, flow cells for next generation sequencing and more.

We partner with our customers to optimize their product design for high volume manufacture with the highest possible quality and reliability at any scale. Downstream commercialization and manufacturing requirements are considered at the early stages of the project, de risking the product development, eliminating unexpected problems, and ensuring products meet. All of our systems and processes at each facility are certified: SCHOTT MINIFAB Phoenix is certified ISO 9001: 2015, ISO 13485: 2016, SCHOTT MINIFAB Melbourne is certified ISO 14001:2015, ISO 45001:2018, and SCHOTT MINIFAB Jena is certified ISO 9001:2015, ISO 13485:2016, ISO 45001:2018, ISO 14001:2015. We are audited annually by our ISO certification partners. This ensures products are fit for their intended purpose and meet the required quality and safety specifications. Products must also comply with regulatory and marketing requirements.

Our partnerships are the cornerstone of our success. To help our customers realize commercial success of their product innovations, we define in-depth NDAs and adhere to strict design and development IP rights. For over 130 years, this has led to long term relationships, build on trust and integrity.

Yes, our manufacturing expertise and infrastructure provide the flexibility and efficiencies to go from prototype to pilot line to high-volume production, at the highest quality possible. Our fit-for-purpose pilot line uses an existing infrastructure, helping control costs and production levels. This provides the flexibility to scale from 100s to 10Ms, efficiently and effectively.

Creating a manufacturing line that is misaligned with demand can result in massive costs due to underutilized labor and exaggerated overheads. SCHOTT MINIFAB affords our clients flexibility when it comes to production volume, ensuring investments made in expensive high-throughput automation equipment are made only when needed, thus providing confidence you will see a return our investment. By partnering with SCHOTT MINIFAB, companies can focus on the core competencies of their business, reduce capital investment in facilities, equipment and technology, and enjoy the production flexibility that comes when working with SCHOTT MINIFAB.